This week, from 5th-14th March is British Science Week, a celebration of science, technology, engineering and maths.

At the Research Complex at Harwell, we are choosing to honour this important week by highlighting the career of one of our early career researchers, Dr Chu Lun Alex Leung, who works within the Materials, Structures and Manufacturing Group, led by Professor Peter Lee. Chu Lun Alex Leung is also a Lecturer in Imaging of Advanced Materials and Manufacturing in the Department of Mechanical Engineering at University College London. Leung’s research focuses on the development of intelligent advanced manufacturing using cutting-edge sensing technologies.

Despite his youth, Dr Leung’s achievements are numerous. His PhD thesis led him to receive 5 individual awards, including the Sir Richard Brook prize (Best Engineering PhD in the UK) as well as the European Powder Metallurgy Association (EPMA) PM Thesis Competition 2019. Besides his industrial experience, he earned a Design London fellowship (2009 – 2011) funded by Imperial College London and the Royal College of Art and worked on a product prototype using directable light technology. He received a First Class Honour degree in Aerospace Materials (MEng) and David West prize (2010) from the Department of Materials, Imperial College London. Prior to his appointment at UCL, he worked as a Postdoctoral Research Fellow at UCL (2018 – 2019) and a Research Associate (2013 – 2017) in the Department of Materials at The University of Manchester, where he obtained his award-winning PhD in Materials.

He talks about his career from his inspirations, what a typical day is like, the challenges faced and his hopes for the future.

1. What is your scientific background?

I read a degree in Materials Science and Engineering, specialising in Aerospace Materials. After that, I spent three years in the steel industry and gained a basic background in process engineering. For the past few years, my research has been focused on additive manufacturing, imaging, and big data analytics.

2. Why did you choose to become a scientist?

I became a scientist because I enjoy solving complex puzzles as well as working with the brightest minds and cutting-edge technologies to tackle scientific challenges, make discoveries, and share meaningful information with others.

3. How did you choose your field of study?

I chose to research additive manufacturing (AM) because I believe AM can create social and economic impacts on a wide range of industries and end-users, from healthcare to automotive, aerospace, and energy sectors, to name a few. These flexible manufacturing technologies can create value-added products with complex shapes and intricate features that cannot be made by other means. It is a real privilege for me to be part of this exciting journey to advance these technologies.

4. Which topic are you working on at the moment? Why did you choose this topic and how do you think you’ll make a difference?

In general, manufacturing processes involve people and complex machinery and hence the processes are difficult to control. To improve both product quality and productivity, this requires intelligent systems that can respond quickly whilst making fine adjustments to refine the process. I am currently leading an interdisciplinary research team to design and implement intelligent systems for the advanced manufacturing process.

Our team is developing new ways to better understand and optimize manufacturing processes, including (1) intelligent laser beam control, (2) development of smart materials, (3) advanced imaging and image processing techniques, and (4) development of in situ diagnostic instruments. Within 10 years, I hope that some of these intelligent systems developed by us can be implemented into the industrial environment and deliver benefits to the end-users.

4. What is a typical day like for you?

I spend one-third of my time reading relevant research, synthesising research ideas, and then turning these ideas into research proposals; one-third of my time is spent performing experiments, data analysis, supervising students and their research projects; the rest of my time is spent on developing and delivering a materials science course to undergraduate students.

5. What are the hardest parts related to this work?

I find the hardest part is achieving a work-life balance as many scientists like me, who enjoy what they do, continue to research outside work hours.

6. Did you ever doubt your abilities as a scientist? Why? How did you handle these situations/feelings?

Yes, I have always doubted my abilities as a scientist because a good scientist is equipped with both soft and hard skills. There is so much to learn, i.e. the glass is always half-full. I guess this is the nature of the job otherwise we won’t need scientists or researchers to tackle big challenges. I always try to be positive. I am not afraid to ask or team-up with other bright minds to solve these big puzzles!

7. Is there any scientific topic (outside of your field of research) that you think should have more scientific attention? Which one?

There are several scientific topics I think we should have more scientific attention.

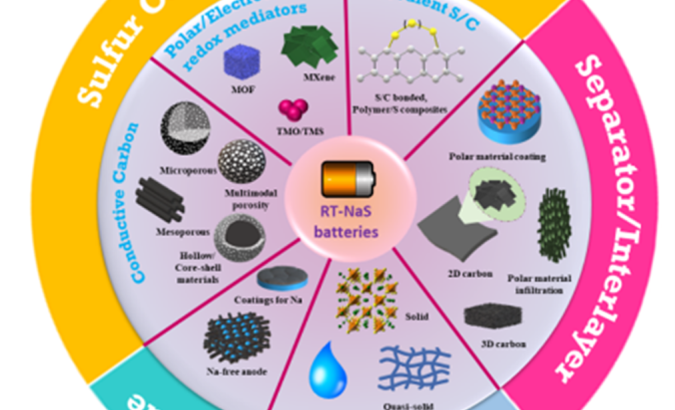

- Effective ways to generate electricity

- Effective ways to obtain clean water

- Reduce carbon emission or develop efficient carbon capture technology

- The rapid development process for vaccinations

8. What are your biggest achievements, and what are your biggest failures?

I am flattered to get asked this question. Getting awards and professional recognitions help to build confidence in what we do. However, it is more important for us to advance new knowledge to the research field as well as helping the present and future society. Although I work 2 – 3 days per annum on outreach activities, i.e. promoting Science, Technology, Engineering, Art, and Mathematics (STEAM) subjects to the public, I think my biggest failure is not doing enough for society. Hopefully, I will be able to address that in future years.

https://mecheng.ucl.ac.uk/people/profile/chu-lun-alex-leung/

Image: EPMA European Powder Metallurgy Association Congress & Exhibition at the MECC in Maastricht, The Netherlands on Monday 14th October 2019. Copyright of Andrew McLeish.