High-fidelity Multi-physics Modeling of Additive Manufacturing: Process, Microstructure, and Property

Introduction

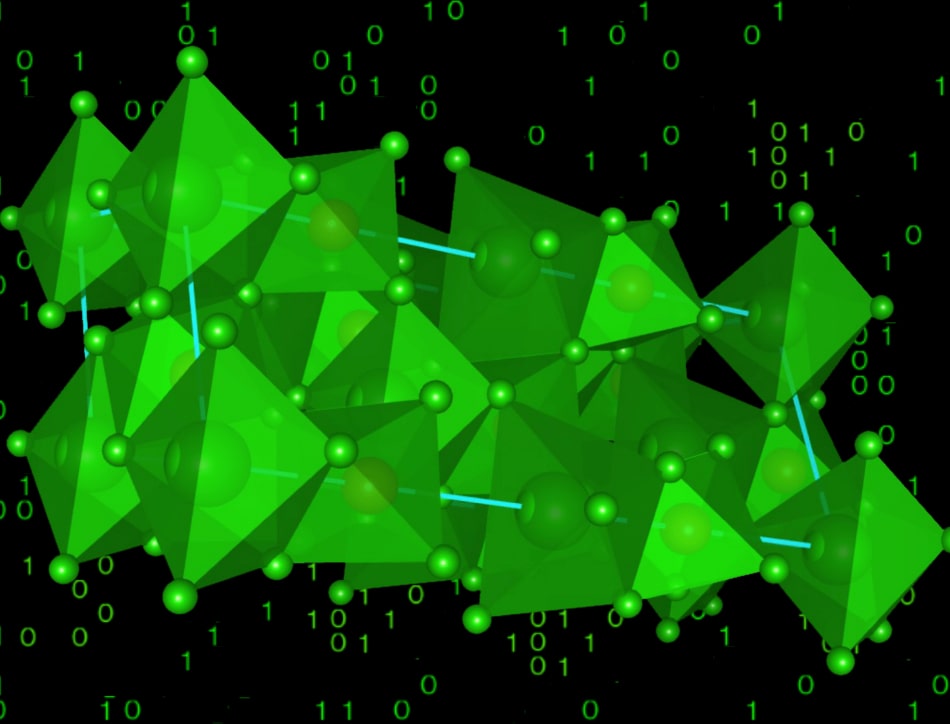

The wide applications of additive manufacturing are hindered by the lack of comprehensive understanding of process-structure-property relationships. To this end, we have developed and seamlessly integrated a series of high-fidelity multi-physics models. Specifically, multiphase flow models using the coupled computational fluid dynamics and discrete element method simulate the powder spreading procedure and powder spattering and denudation phenomena in the powder melting procedure. The powder melting model is powerful to reproduce the molten pool flow and relevant defects (e.g., lack-of-fusion and keyhole pores) by incorporating the major physical factors, e.g., the composition-dependent evaporation and physically-informed heat source models. The microstructure evolutions at both the grain- and dendrite- scales are modelled using the phase field and cellular automaton methods. The mechanical properties and thermal stresses are simulated using the crystal plasticity finite element model, which incorporates the realistic geometry (rough surfaces and voids), temperature profiles and microstructures. These models have proven powerful in revealing the physical mechanisms and optimizing the manufacturing processes, which have been well validated against various experiments, particularly in-situ observations.